Amarimu ahlala isikhathi eside kakhulu ancike endaweni kanye nezinto ezibonakalayo zokusetshenziswa. Izinhlobo zamarimu ezilandelayo zibonisa ukuqina okuhlukile ezimeni ezahlukene:

1. Izinsimbi zensimbi

Ukuqina: Amarimu ensimbi angolunye lwezinhlobo zamarimu ahlala isikhathi eside, ikakhulukazi uma engaphansi komthelela omkhulu noma imithwalo esindayo. Ziyakwazi ukumelana nomthelela omkhulu futhi zingamelana nemithelela ngaphandle kokuqhekeka noma ukuphuka kalula.

Izimo ezisebenzayo: Ifanele indawo enzima, izimoto ezingekho emgwaqeni, amaloli asindayo, nemishini yokwakha. Ifanele ikakhulukazi izindawo ezinezimo ezinzima njengezimayini nezindawo zokwakha.

Ukulungiseka: Uma amarimu ensimbi egobile, ngokuvamile angalungiswa ngamathuluzi okulungisa alula ngaphandle kokushintshwa.

Isifinyezo: Izinsimbi zensimbi ziyisinqumo esihlala isikhathi eside, ikakhulukazi esilungele imithwalo esindayo kanye nezimo zomgwaqo ezinzima ngenxa yamandla awo aphezulu nokuqina.

2. Amarimu e-alloy enziwe nge-aluminium

Ukuqina: Amarimu engxube ye-aluminiyamu efojiwe anamandla aphezulu kanye nokuqina kunamarimu avamile we-aluminium alloy cast. Inqubo yokubumba ibenza baminyene, bamelane nomthelela, futhi babe lula.

Izimo ezisebenzayo: Ifanele izimoto ezisebenza kahle kakhulu, ama-SUV, nezinhlelo zokusebenza ezidinga ukulayishwa kalula. Basebenza kahle ekushayeleni emadolobheni nasezimeni zemigwaqo emikhulu.

Ukulungiseka: Uma umugqa we-aluminium omgunyathi sewonakele, kuba nzima ukukhanda futhi ngokuvamile udinga ukushintshwa.

Isifinyezo: Amarimu engxube ye-aluminium efojiwe athola ibhalansi enhle phakathi kwamandla nokukhanya futhi angamarimu e-aluminium ahlala isikhathi eside.

3. Magnesium alloy rims

Ukuqina: Amarimu engxubevange ye-Magnesium alula kakhulu, kodwa awaqinile futhi awakwazi ukumelana njengensimbi noma amarimu e-aluminium enziwe mbumbulu. Afanele izikhathi lapho ukusebenza kunokuqina kulandelwa.

Izimo ezisebenzayo: Ikakhulukazi ezisetshenziswa emijahweni yezimoto ezisezingeni eliphezulu, ezingafanele ukushayela kwansuku zonke noma izindawo ezinokhahlo.

Ukulungiseka: Izinsimbi ze-Magnesium alloy zintekenteke, futhi uma zonakele, ukulungisa kuba nzima kakhulu futhi ngokuvamile kudinga ukushintshwa.

Isifinyezo: Nakuba ukukhanya, amarimu engxubevange ye-magnesium awaqinile njengensimbi noma i-aluminium efojiwe, futhi afanele imijaho noma imicimbi yezemidlalo enezidingo eziphezulu ezingasindi.

4. Izinsimbi ze-carbon fibre

Ukuqina: Amarimu e-Carbon fiber alula kakhulu, kodwa anokuqina okubi futhi alinyazwa kalula umthelela, ofanele izinhlelo zokusebenza ezidinga ukukhanya okukhulu nokusebenza okuphezulu.

Izimo ezisebenzayo: Izimoto zemijaho ephezulu noma ezemidlalo ezisebenza kahle kakhulu, ngokuvamile ezisetshenziswa ethrekhi.

Ukulungiseka: Uma sekonakele, amarimu e-carbon fibre cishe akunakwenzeka ukukhanda futhi ngokuvamile adinga ukushintshwa ngokuphelele.

Isifinyezo: Amarimu e-Carbon fiber ahamba phambili ekukhanyeni okwedlulele, kodwa awafanele izindawo ezidinga ukuqina okuphezulu.

Ngakho-ke, amarimu ensimbi yiwona ahlala isikhathi eside kakhulu futhi afaneleka ngokukhethekile ezindaweni zokusebenza ezisindayo (njengezimayini, izindawo zokwakha, njll.) ezidinga ukumelana nomthelela ophezulu kanye namandla okuthwala umthwalo.

Amarimu engxube ye-aluminium eyakhiwe ahlala isikhathi eside futhi asebenza kahle kakhulu. Zinokulingana okuhle phakathi kokuqina nokungasindi futhi zilungele izimoto ezisebenza kahle kakhulu nokushayela kwansuku zonke.

Uma ukuqina kuwukucatshangelwa okuyinhloko, ikakhulukazi ezindaweni ezinokhahlo, amarimu ensimbi ayisinqumo esingcono kakhulu. Uma kokubili ukusebenza nokuqina kuyadingeka, amarimu e-aluminium alloy akhiwe yisinqumo esifanele.

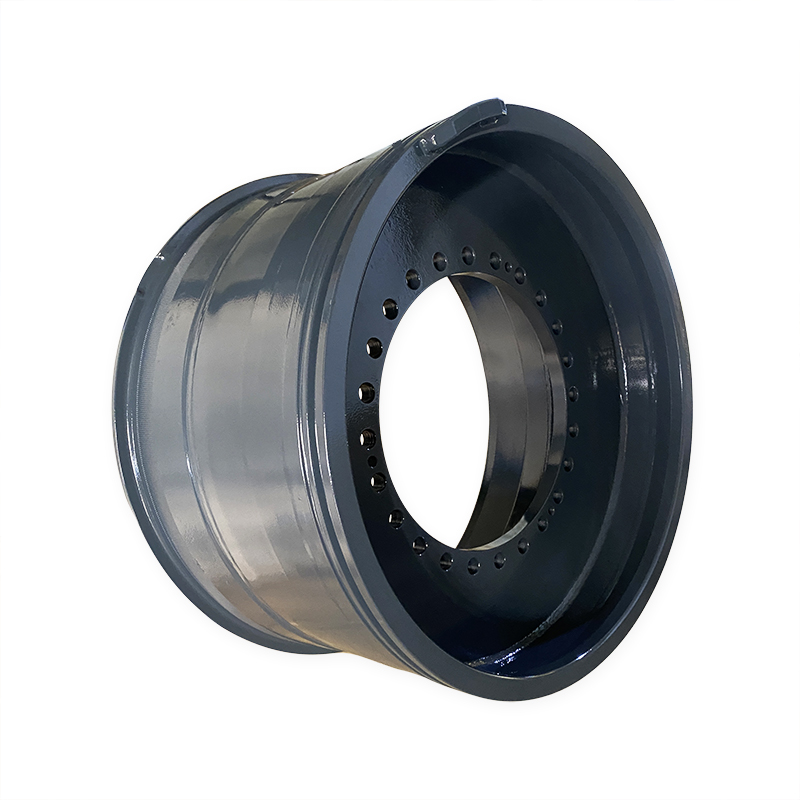

Ukukhetha amarimu afanele akukwazi nje ukuthuthukisa ukusebenza kahle kwemoto, kodwa futhi kwandise impilo yesevisi yamasondo nemishini. Ngokwesibonelo,amarimu angu-17.00-35/3.5 osayizi asetshenziswa amaloli amakhulu aqinile okulahla izimoto zezimayini

Ubuchwepheshe bethu buvuthwe kakhulu ekukhiqizeni amarimu eloli yokulahla aqinile. Okulandelayo amanye amasayizi esingawakhiqiza.

| Iloli le-Rigid Dump | 15.00-35 | Iloli le-Rigid Dump | 29.00-57 |

| Iloli le-Rigid Dump | 17.00-35 | Iloli le-Rigid Dump | 32.00-57 |

| Iloli le-Rigid Dump | 19.50-49 | Iloli le-Rigid Dump | 41.00-63 |

| Iloli le-Rigid Dump | 24.00-51 | Iloli le-Rigid Dump | 44.00-63 |

| Iloli le-Rigid Dump | 40.00-51 |

Njengoba indawo yezimayini ivamise ukuba namagquma futhi ihlanganisa indawo eyinkimbinkimbi njengemigodi, amadwala, udaka, imiqansa, njll., ukukhetha amarimu anosayizi omkhulu ofanele kuhlanganiswe namathayi afanele kungakhuphula indawo evulekile yemoto, kuthuthukise ukudlula kwemoto. , basize bawele kahle izithiyo noma indawo engalingani, futhi bathuthukise ukuzinza. Ukwengeza, izimoto zezimayini (njengamaloli amakhulu ezimayini nezilayishi) ngokuvamile zidinga ukuthwala imithwalo esindayo, ngokuvamile amathani noma ngisho namakhulu amathani ensimbi noma impahla. Amarimu ensimbi amakhulu angahlonyiswa ngemithwalo emikhulu, anikeze indawo enkulu yokuxhumana nomthwalo kanye nomthamo wokuthwala, ngaleyo ndlela asabalalisa imithwalo esindayo ngokulinganayo futhi anciphise ukulimala kwamasondo.

Indlela yokukhetha i-rim yensimbi efanele?

Ukukhetha i-rim yensimbi efanele kudinga ukucatshangelwa okuphelele kohlobo lwemoto, indawo yokusebenzisa kanye nezidingo ezithile. Okulandelayo yimibandela yokukhetha eyinhloko nezinyathelo ezimbalwa:

1. Qonda uhlobo nenjongo yemoto

Izimoto ezahlukene kanye nezimo zohlelo zinezidingo ezihlukene zamarimu. Izimoto zezimayini, izinto zokwakha, amaloli amakhulu nezimoto ezingekho emgwaqeni ngokuvamile zidinga amarimu ensimbi aqinile futhi ahlala isikhathi eside, kuyilapho izimoto zabagibeli noma izimoto ezincane zingase zicabangele isisindo nokubukeka kwamarimu ngaphezulu.

Imishini esindayo nezimoto zezimayini: zidinga amarimu ensimbi aqinile, aqinile akwazi ukumelana nemithwalo ephezulu kanye nezimo zokusebenza ezimbi kakhulu.

Amaloli avamile noma izimoto ezingekho emgwaqeni: Ungase udinge rimu elishaya ibhalansi phakathi kwamandla nesisindo.

2. Khetha usayizi ofanele ngokwezicaciso zesondo

Usayizi werimu: Qinisekisa ukuthi usayizi (ububanzi nobubanzi) berimu buhambisana nesondo. Ububanzi berimu obufanele ngokuvamile buphawulwa odongeni oluseceleni lwesondo, njengokuthi "17", okubonisa ukuthi i-rim engamayintshi angu-17 iyadingeka. Ububanzi besondo nerimu nakho kudinga ukuhambisana ukuze kuqinisekiswe ukuphepha nokusebenza kokushayela.

Ukukhetha ububanzi: Ububanzi berimu kufanele bube buncane kancane kunobubanzi besondo ukuze kuqinisekiswe ukuthi isondo lingahlanganiswa ngokuqinile emgqeni kuyilapho ligcina umfutho womoya ofanele nokuzinza.

3. Hlola umthamo womthwalo werimu

Isilinganiso somthwalo: Umthamo womthwalo wamarimu ensimbi ubaluleke kakhulu, ikakhulukazi ezimotweni ezinzima. Uma ukhetha, qiniseka ukuthi umthamo womthwalo werimu ungamelana nesisindo esiphelele semoto kanye nesisindo sayo esiphezulu uma ilayishwe ngokugcwele. Umthamo wokulayisha werimu ngokuvamile ungatholwa kusukela ekucacisweni komkhiqizi.

Izidingo zomthwalo: Uma imoto idinga njalo ukuthutha izinto ezisindayo noma ukuhamba ezindaweni ezimbi, kuyadingeka ukukhetha amarimu ensimbi anezilinganiso zomthwalo ophezulu ukuze ugweme ukuguga ngaphambi kwesikhathi noma ukulimala.

4. Cabanga ngokusuka kwerimu

I-Offset (inani le-ET): I-Offset ibhekisela ebangeni eliphakathi kwendawo yokukhweza urimu kanye nomugqa omaphakathi worimu. I-offset efanele iqinisekisa ukuthi isondo lisebenza kahle nesistimu yokumiswa kwemoto. I-offset enhle kakhulu ingase ibangele isondo ukuthi lishwabane ngaphakathi, kuthinte isiteringi nokumiswa, kuyilapho i-offset engalungile kakhulu ingase ibangele isondo ukuba liphume kakhulu, kwandise umthwalo ezingxenyeni ezimisiwe.

Izidingo zokucaciswa kwemoto: Khetha irimu elifanele ngokuya ngemingcele enconyiwe ye-offset enikezwe umenzi wemoto ukugwema ukuphatha noma izinkinga zokuguga kwamathayi.

5. Ukumelana nokugqwala nokwelashwa kokumboza

Amarimu ensimbi ajwayele ukugqwala lapho evezwe ezindaweni ezingaphandle isikhathi eside, ngakho-ke kubalulekile ukukhetha amarimu anezingubo ezinhle zokulwa nokugqwala. Izimoto zemishini yezimayini nezokwakha zidinga izinga eliphezulu lokuvikela ukugqwala.

Ukukhethwa kokumboza: Ukufakwa kwe-galvanizing, i-powder coating noma enye i-anti-rust coating ingathuthukisa kakhulu ukumelana nokugqwala komugqa, ikakhulukazi ezindaweni ezimanzi, ezinodaka nezinothuli.

6. Naka inqubo yokukhiqiza kanye nekhwalithi yamarimu

Inqubo yokukhiqiza: Khetha amarimu ensimbi akhiqizwa ngezinqubo zokushisela zekhwalithi ephezulu kanye nokwakheka ukuze kuqinisekiswe amandla azo esakhiwo nokuqina. Amarimu anobuciko obumpofu angase abe nezinkinga ezifana nokushisela okuxekethile kanye nokukhubazeka kwempahla, okungaholela kalula ekulimaleni kwamarimu.

Ukuqinisekisa namazinga: Qiniseka ukuthi amarimu ahlangabezana nezindinganiso zekhwalithi ezifanele nezitifiketi (ezifana ne-ISO, i-JIS noma i-SAE), ezingaqinisekisa ukuphepha nokuthembeka kwamarimu ngesikhathi sokuklama nenqubo yokukhiqiza.

7. Cabanga ngesisindo samarimu

Nakuba amarimu ensimbi ngokuvamile esindayo kunamarimu e-aluminium, amarimu ensimbi ahlukene nawo angahluka ngesisindo. Ezimotweni ezidinga ukuhamba njalo, amarimu ensimbi anganciphisa isisindo semoto, athuthukise ukusebenza kahle kukaphethiloli, futhi athuthukise ukuphatha.

8. Naka ukuhambisana kwesesekeli

Iphethini yehabhu yebhawodi: Qiniseka ukuthi inombolo nokuhlelwa kwezimbobo zebhawodi kurimu kufana nehabhu yemoto. Iphethini yebhawudi (njenge-4×100, 5×114.3) kufanele ahambisane namarimu okuqala emoto ukuze kuqinisekiswe ukufakwa ngokuphephile.

Usayizi wembobo emaphakathi: Imbobo emaphakathi yerimu yensimbi kufanele ifaniswe ngokunembile nehabhu lesondo lemoto ukuze kugwenywe ukonakala kwerimu noma izingozi zokuphepha ngenxa yokuxega.

9. Isabelomali kanye nezindleko zokunakekela

Amarimu ensimbi ngokuvamile ashibhile kunamarimu enziwe ngezinye izinto, kodwa intengo izohluka kuye ngekhwalithi nokwelashwa kokuqeda ukugqwala. Khetha izinga eliphezulu, izinsimbi zensimbi ezihlala isikhathi eside, nakuba izindleko zokuqala zingase zibe phezulu kancane, kodwa izindleko zokulungisa zizoba ngaphansi ekusebenziseni isikhathi eside.

Uma ukhetha irimu lensimbi elifanele, qala ngokuqinisekisa ukuthi usayizi werimu, umthamo wokulayisha kanye ne-offset kuyahlangabezana nezidingo zemoto, futhi ube nokuvikela ukugqwala okuhle kanye nenqubo yokukhiqiza. Uma imoto isetshenziselwa imisebenzi enzima kakhulu noma izindawo ezinokhahlo, ukuqina kanye nomthamo ophezulu wokuthwala umthwalo yizici ezibalulekile; ezimotweni ezijwayelekile ezingekho emgwaqeni noma amaloli, ibhalansi phakathi kwamandla nesisindo kuyadingeka.

Singabaklami nabakhi bamasondo angaphandle komgwaqo wokuqala eChina, futhi singochwepheshe abahamba phambili emhlabeni ekwakhiweni nasekukhiqizeni ingxenye yamarimu. Yonke imikhiqizo yakhelwe futhi ikhiqizwa ngokwezinga eliphezulu kakhulu, futhi sineminyaka engaphezu kwengama-20 yesipiliyoni sokukhiqiza amasondo. Sibandakanyeka kakhulu emishinini yobunjiniyela, amarimu emoto yezimayini, amarimu e-forklift, amarimu ezimboni, amarimu ezolimo nezinye izesekeli namathayi. Singabahlinzeki berimu bokuqala e-China bemikhiqizo eyaziwa kakhulu njengeVolvo, Caterpillar, Liebherr, kanye no-John Deere.

Sinethimba locwaningo nentuthuko elakhiwe onjiniyela abakhulu nochwepheshe bezobuchwepheshe, eligxile ocwaningweni nasekusetshenzisweni kobuchwepheshe obusha, kanye nokugcina isikhundla esiphambili embonini. Senze uhlelo oluphelele lwesevisi yangemuva kokuthengisa, oluhlinzeka ngosekelo lwezobuchwepheshe olufika ngesikhathi nolusebenzayo kanye nokugcinwa kokugcinwa kokuthengisa ngemva kokuthengisa ukuze siqinisekise ukuthi amakhasimende anolwazi olushelelezi ngesikhathi sokusetshenziswa. Uma unezinkinga nemibuzo odinga ukuxhumana nathi, ungaxhumana nathi!

Okulandelayo amasayizi ahlukahlukene amarimu inkampani yethu engawakhiqizela amasimu ahlukene:

Osayizi bemishini yobunjiniyela: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 20-10-13, 2-13 25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Osayizi bezimayini: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-305-305-305, 30-30-30. 49 , 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Osayizi be-Forklift yilaba: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15-05-15, 5. 15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Usayizi wezimoto zezimboni yilezi: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 1000-220, 1000x12, 7XX15, 8XX156.5, 16x17, 13X15 .5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Osayizi bemishini yezolimo: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 8x18, W , W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x16x30, W14x6x30, x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Imikhiqizo yethu inekhwalithi esezingeni lomhlaba.

Isikhathi sokuthumela: Oct-29-2024