Isho ukuthini i-TPMS ngamathayi emoto yokwakha?

I-TPMS (Tire Pressure Monitoring System) yamathayi ezimoto zokwakha iwuhlelo oluqapha umfutho wesondo nezinga lokushisa ngesikhathi sangempela, olusetshenziselwa ukuthuthukisa ukuphepha kwemoto, ukunciphisa ubungozi bokulimala kwamasondo, nokuthuthukisa ukusebenza kahle kukaphethiloli. I-TPMS ibaluleke kakhulu ezintweni ezisindayo nasezimotweni zokwakha (njengamaloli ezimayini, ama-excavators, ama-loaders, njll.) ngoba lezi zimoto zivame ukusebenza ngaphansi kwezimo ezimbi kakhulu futhi ukusebenza kwamathayi kubalulekile ekuphepheni nasekusebenzeni kahle.

Imisebenzi nezindima ze-TPMS:

1. Ukuqapha ngesikhathi sangempela umfutho wesondo:

- Uhlelo lwe-TPMS luhlala luqapha umfutho womoya ethayini ngezinzwa ezifakwe ethayini ngalinye. Uma umfutho womoya uphansi noma ungaphezulu kwenani elijwayelekile elimisiwe, isistimu izokhipha isexwayiso ukukhumbuza umshayeli ukuthi athathe isinyathelo.

- Lokhu kusiza ukugwema ukuqhuma kwamasondo kanye nokuguga ngokweqile okubangelwa ukucindezela kwesondo okuphansi, noma ukunciphisa ukubamba kanye nokushisa ngokweqile kwesondo okubangelwa ukucindezela okukhulu kwesondo.

2. Ukuqapha ngesikhathi sangempela izinga lokushisa lamasondo:

- Ngaphezu kokucindezela komoya, i-TPMS iphinde iqaphe izinga lokushisa kwamasondo. Uma izimoto zokwakha zisebenza isikhathi eside noma zishayela ngaphansi kwezinga lokushisa eliphezulu nezimo zomgwaqo ezinzima, amathayi athambekele ekushiseni ngokweqile, okwandisa ingozi yokuhluleka. Ukuqapha izinga lokushisa kungasiza opharetha babone izinkinga ezingase zibe khona kusenesikhathi futhi bavimbele ukungasebenzi kwamasondo noma izingozi zomlilo.

3. Thuthukisa ukusebenza kahle kukaphethiloli:

- Umfutho wesondo ophansi uzokwandisa ukumelana nokugoqeka kwesondo, okuholela ekusetshenzisweni kukaphethiloli okwandisiwe. Uhlelo lwe-TPMS lungasiza ekuqinisekiseni ukuthi isondo lihlala lisezingeni eliphezulu lokucindezela, ngaleyo ndlela linciphise ukusetshenziswa kukaphethiloli futhi lithuthukise umnotho wemoto.

4. Nweba impilo yamasondo:

- Ngokugcina ukucindezela kwesondo okulungile nokuqapha izinga lokushisa kwamasondo, i-TPMS inganciphisa kakhulu ukuguga kwamasondo futhi yandise ukuphila kwamasondo, ngaleyo ndlela inciphise imvamisa yokushintshwa kwamasondo futhi yehlise izindleko zokulilungisa.

5. Thuthukisa ukuphepha:

- Uma izimoto zobunjiniyela zisebenza ezindaweni ezinokhahlo, izinkinga ezinamasondo zingabangela ukuthi okokusebenza kuhluleke ukulawula noma kubangele izingozi ezimbi zokuphepha. I-TPMS ingabona izinkinga kusenesikhathi, ivimbele izingozi ezingaba khona, futhi iqinisekise ukuphepha kokusebenza.

Isebenza kanjani i-TPMS:

Uhlelo lwe-TPMS ngokuvamile luqukethe izinzwa ezifakwe ethayini, imojula yokulawula emaphakathi, kanye nedivayisi yokubonisa. Inzwa ikala umfutho womoya nezinga lokushisa ethayeni futhi idlulisela idatha kusibonisi somshayeli noma kusistimu yesixwayiso ngamasignali angenantambo. Uma ukucindezela komoya noma izinga lokushisa lidlula ibanga elivamile, isistimu izokhipha isexwayiso ukuze uvumele opharetha ukuthi athathe izinyathelo ezifika ngesikhathi.

Ukubaluleka kwe-TPMS ezimotweni zokwakha:

Izimoto zokwakha zivame ukusebenza ngaphansi kwemithwalo esindayo, indawo eyinkimbinkimbi nesimo sezulu esibi, kanye nokucindezela kwamasondo nokulawulwa kwezinga lokushisa kubalulekile. Uhlelo lwe-TPMS lungasiza abaqhubi ukuthi baqaphe kangcono isimo samasondo futhi banciphise ingozi yokuphelelwa yisikhathi okungalindelekile, ukulimala kwamasondo noma izingozi zokuphepha, ikakhulukazi ezimayini, ezindaweni zokwakha nezinye izindawo lapho ukusebenza kwemishini kufuna kakhulu.

Kafushane, i-TPMS idlala indima ebalulekile ekuphathweni kwamasondo emoto yokwakha, ukusiza ukuthuthukisa ukuphepha, ukwenza kahle ukusebenza nokunciphisa izindleko zokusebenza.

Amasondo emoto yokwakha kanye namasondo emoto yokwakha yizingxenye ezibalulekile zezimoto zokwakha, ezithwala imithwalo esindayo futhi zivumelane nezimo zokusebenza eziyinkimbinkimbi.

Singumklami nomkhiqizi wamasondo angaphandle komgwaqo waseChina onguNombolo 1, futhi singochwepheshe abahamba phambili emhlabeni ekuklameni nasekukhiqizeni ingxenye yamarimu. Yonke imikhiqizo yakhelwe futhi ikhiqizwa ngokwezinga eliphezulu kakhulu, futhi sineminyaka engaphezu kwengama-20 yesipiliyoni sokukhiqiza amasondo. Singabahlinzeki berimu bokuqala e-China bemikhiqizo eyaziwa kakhulu njengeVolvo, Caterpillar, Liebherr, kanye no-John Deere.

Inkampani yethu ibandakanyeka kakhulu emikhakheni yemishini yokwakha, izinsimbi zezimayini, izinsimbi ze-forklift, izinsimbi zezimboni, izinsimbi zezolimo, ezinye izingxenye zamarimu namathayi.

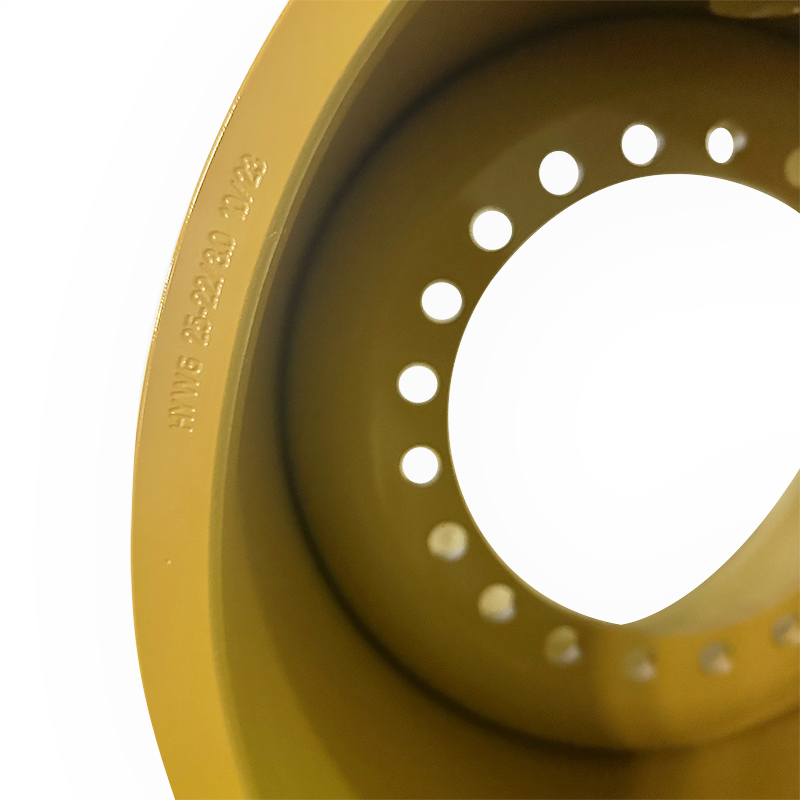

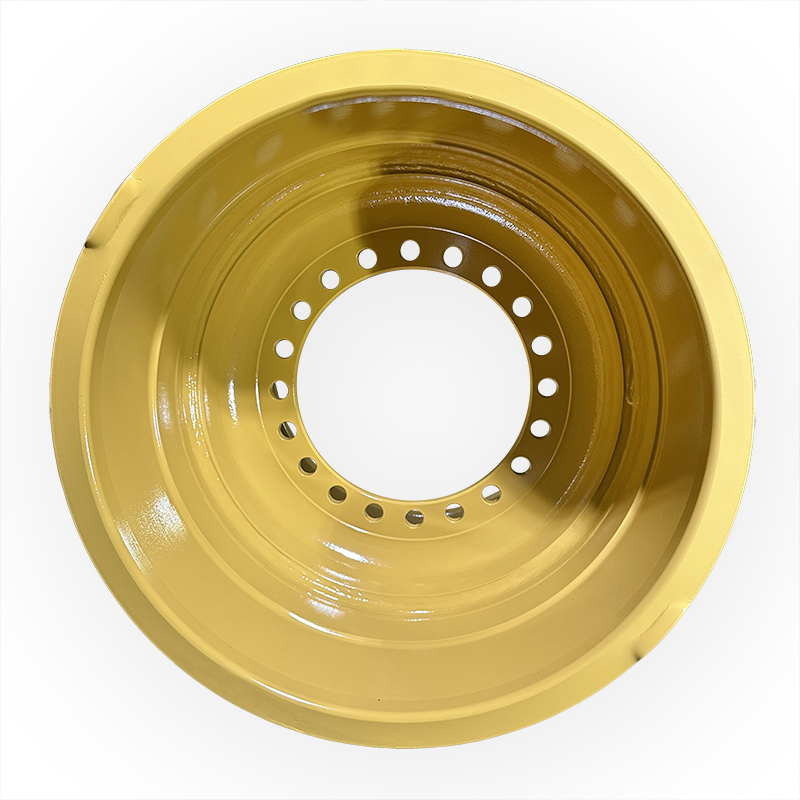

I22.00-25/3.0 amarimuesinikeze i-Caterpillar ukuze isetshenziswe kuma-wheel loader ezimotweni zokwakha ziye zaqashelwa ngazwi linye ngamakhasimende.

“22.00-25/3.0” kuyindlela yokubonisa ukucaciswa kwesondo nosayizi wamarimu, okuvamise ukusetshenziswa ezintweni ezisindayo njengemishini emikhulu yokwakha, amaloli ezimayini, izilayishi, njll. Incazelo ethile imi kanje:

1.22.00: Ibonisa ububanzi besondo ngamayintshi. Lokhu kusho ukuthi ububanzi be-cross-sectional wesondo bungama-intshi angu-22.

2. 25: Ikhombisa ububanzi berimu (ihabhu lamasondo), futhi ngama-intshi. Lokhu kusho ukuthi ububanzi berimu elifanele isondo ngamasentimitha angu-25.

3. /3.0: Leli nani ngokuvamile libonisa ububanzi berimu ngamayintshi. 3.0 kusho ukuthi ububanzi berimu bungamayintshi angu-3. Le ngxenye ingusayizi wesakhiwo wesondo elifakwe ku rimu, okuqinisekisa ukuthi isondo nomphetho kuyahambisana.

Lokhu kucaciswa kwamathayi namarimu kuvame ukusetshenziselwa imishini emikhulu yokwakha, efana nezilayishi, ogandaganda, amaloli ezimayini, izibambi zeziqukathi, njll., ngoba le mishini eyimishini idinga imithwalo ephezulu namathayi anamandla ukuze ibhekane nezindawo zokusebenza eziyinkimbinkimbi.

Izici eziyinhloko:

Umthamo omkhulu womthwalo: amathayi abanzi namarimu amakhulu angakwazi ukumelana nezisindo eziphakeme futhi afanelekele imisebenzi enzima.

Ukumelana nokugqokwa okuqinile: amathayi alokhu kucaciswa ngokuvamile asetshenziswa ezindaweni ezinokhahlo futhi anokumelana nokugqokwa okuqinile kanye nokumelana nomthelela.

Ukuzinza okuhle: ububanzi obukhulu kanye namathayi abanzi ahlinzeka indawo enhle yokuxhumana futhi angagcina uzinzo endaweni evulekile noma emangelengele.

Le nhlanganisela yesondo nerimu ngokuvamile inikeza ukwesekwa okuthembekile kwezimoto ezinzima, iqinisekisa ukuphepha nokusebenza kahle ngaphansi kwezimo zokusebenza ezinzima.

Kungani Abalayishi Amasondo Besebenzisa Amathayi Aqinile?

Izilayishi zamasondo zisebenzisa amathayi aqinile ngezikhathi ezithile ezikhethekile, ikakhulukazi ukuze zibhekane nezimo ezinzima zokusebenza nezimo zokusebenza ezinzima. Izizathu eziqondile zihlanganisa izici ezilandelayo:

1. Ukumelana nokubhoboza okuqinile

Indawo yokusebenza eyinkimbinkimbi: Izilayishi zamasondo zivame ukusebenza ezindaweni zokwakha, ezimayini, ezindaweni zokulahla imfucuza nakwezinye izindawo. Kungase kube nenani elikhulu lamatshe acijile, izinsimbi zensimbi, ingilazi ephukile, njll. phansi kulezi zindawo, ezingabhoboza kalula amathayi avamile womoya.

Amathayi aqinile awanawo umgodi wangaphakathi: Njengoba amathayi aqinile angenawo ukwakheka kwe-inflatable futhi agcwele ngokuphelele irabha ngaphakathi, ngeke avuze noma aqhume ngenxa yokubhoboza njengamathayi omoya, ngaleyo ndlela anciphise kakhulu isikhathi sokuphumula kanye nezindleko zokunakekela okubangelwa ukulimala kwamasondo.

2. Ukumelana nokugqoka kanye nempilo ende yesevisi

Ukusebenza okunamandla: Izilayishi zamasondo zivame ukudinga ukusebenza isikhathi eside nokushuba okuphezulu, futhi amathayi azobhekana nokungqubuzana nokuguga okukhulu. Amathayi aqinile anokumelana nokuguga okuphakeme kunamathayi avamile omoya ngenxa yokuminyana kwawo okuphezulu kwezinto ezibonakalayo, ngakho anempilo ende yesevisi ngaphansi kwezimo ezinzima.

3. Ayinasondlo

Asikho isidingo sokwenyuka kwamandla emali njalo noma ukulungiswa: Amathayi aqinile aqeda inkinga yokwehla kwamandla emali amathayi, ukutholwa nokulungiswa kwamasondo. Ezikhathini ezidinga ukusebenza okuqhubekayo, ukusetshenziswa kwamathayi aqinile kunganciphisa kakhulu isikhathi sokuphumula esibangelwa izinkinga zamasondo, ngaleyo ndlela kuthuthukise ukusebenza kahle kokukhiqiza.

4. Umthamo oqinile womthwalo osindayo

Imelana nemithwalo emikhulu: Izilayishi zamasondo ngokuvamile zidinga ukuthwala nokuthutha izinto ezisindayo. Amathayi aqinile anomthamo oqinile wokuthwala umthwalo kunamathayi omoya futhi awakhubazeki kalula noma alimale ngenxa yokugcwala ngokweqile. Zifanele ikakhulukazi izikhathi lapho izinto ezisindayo zidinga ukuthuthwa njalo.

5. Ukuzinza okuhle

Ukusebenza okuqinile kwe-anti-seismic: Amathayi aqinile anesakhiwo esiqinile namandla afanayo. Lapho zithutha izinto ezisindayo, ngeke zibe nokushintshashintsha okukhulu okunwebeka njengamathayi omoya, ngakho-ke zinganikeza ulwazi lokushayela oluzinzile, ikakhulukazi emhlabathini omazombezombe.

6. Ifanele ukusebenza kwejubane eliphansi kanye nebanga elifushane

Ukusetshenziswa kwamasondo aqinile ngabalayishi bamasondo ezindaweni zokusebenza ngokweqile kungathuthukisa kakhulu ukuthembeka kwawo, ukuqina nokuphepha kwawo, futhi kunciphise izindleko zokunakekela amathayi. Amathayi aqinile ayisinqumo esihle ngaphansi kwezimo ezinobungozi obukhulu, ezilayisha kakhulu, nezinejubane eliphansi.

Okulandelayo amasayizi ahlukahlukene amarimu inkampani yethu engawakhiqizela amasimu ahlukene:

Osayizi bemishini yobunjiniyela: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 20-13, 20-25 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-25.

Osayizi bezimayini: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-305-304, 31-30, 31 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Osayizi be-Forklift yilaba: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-10-15, 5, 5 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Osayizi bezimoto zezimboni yilezi: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.21x16.5, 8.21x16.5 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x2

Osayizi bemishini yezolimo yilaba: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, W8, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18, 18. 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW12x50x28, DW15x5x28 DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Imikhiqizo yethu inekhwalithi yomhlaba.

Isikhathi sokuthumela: Oct-10-2024